Provides

the

functions

to

track

all

items

(work

in

progress

&

finished

goods)

throughout

the

operation.

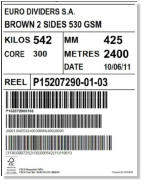

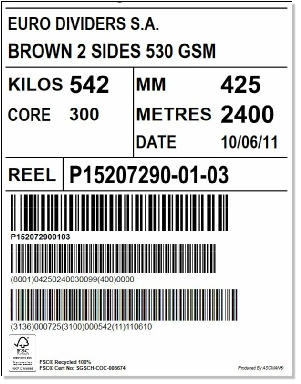

All

items

are

bar-coded

to

allow

automated

recording

and

tracking

of

stock

movements

and

consumption.

Any

number

of

Warehouses

can

be

managed,

each

of

which

can

have

multiple

bays.

Each

bay

can

be

further

segregated

into

bins. Warehouses can be an actual store or warehouse, or a designated area of your shop floor.

Warehouses

can

be

optimised

through

configurable

‘putaway’

logic.

In

addition,

the

system

can

manage

consignment stocks and your remote & third party warehousing requirements.

Items

are

tracked

as

they

move

between

Work

Centres

and

around

warehouses.

When

items

are

moved

between

Depots

and

Bays,

the

new

location

is

logged.

Locations

can

be

confirmed

by

means

of

check

codes

for

each Bay and Depot.

ascman : inventory control

© ascman ltd 2018

“Specialist IT solutions for roll-based, cores and flat sheet industries”

Tracks WIP & FG

Warehouse Optimisation

Sophisticated Stock Search

Allows Re-Grading

Stock Snapshots

Stock Reconciliation

The

system

can

be

interrogated

by

Location,

Product,

Product

Status,

Product

Characteristics

(Width,

Diameter,

Centre

Size,

Shape,

etc),

Category,

Customer,

or

any

combination

of

these.

This

helps you quickly find particular stock types anywhere inside your organisation.

The

system

allows

any

item

in

stock

to

be

re-graded.

This

feature

covers

eventualities

such

as

damaged

material

being

re-processed.

For

such

an

event,

the

reason

and

time

of

the

re-grade

is

recorded

and

an

audit

trail

kept.

Once

processed,

these

items

are

re-entered

into

stock

under

the

new product details.

Stock

snapshots

can

be

taken

at

any

time.

Stock

taking

and

reconciliation

can

be

carried

out

at

any

time by specific locations. Normally, RF scanners are used to record all items at a location.

Provides

the

functions

to

track

all

items

(work

in

progress

&

finished

goods)

throughout

the

operation.

All

items

are

bar-coded

to

allow

automated

recording

and

tracking

of

stock

movements

and

consumption.

Any

number

of

Warehouses

can

be

managed,

each

of

which

can

have

multiple

bays.

Each

bay

can

be

further

segregated

into

bins.

Warehouses

can

be

an

actual

store

or

warehouse,

or

a

designated area of your shop floor.

Warehouses

can

be

optimised

through

configurable

‘putaway’

logic.

In

addition,

the

system

can

manage

consignment

stocks

and

your

remote

&

third

party

warehousing

requirements.

Items

are

tracked

as

they

move

between

Work

Centres

and

around

warehouses.

When

items

are

moved

between

Depots

and

Bays,

the

new

location

is

logged.

Locations

can

be

confirmed

by

means

of

check

codes

for

each

Bay

and

Depot.

ascman : inventory

© ascman ltd 2020

“Specialist IT solutions for roll-based,

cores and flat sheet industries”

Tracks WIP & FG

Warehouse

Optimisation

Sophisticated Stock

Search

Allows Re-Grading

Stock Snapshots

Stock

Reconciliation

The

system

can

be

interrogated

by

Location,

Product,

Product

Status,

Product

Characteristics

(Width,

Diameter,

Centre

Size,

Shape,

etc),

Category,

Customer,

or

any

combination

of

these.

This

helps

you

quickly

find

particular

stock

types

anywhere

inside

your organisation.

The

system

allows

any

item

in

stock

to

be

re-

graded.

This

feature

covers

eventualities

such

as

damaged

material

being

re-processed.

For

such

an

event,

the

reason

and

time

of

the

re-

grade

is

recorded

and

an

audit

trail

kept.

Once

processed,

these

items

are

re-entered

into

stock under the new product details.

Stock

snapshots

can

be

taken

at

any

time.

Stock

taking

and

reconciliation

can

be

carried

out

at

any

time

by

specific

locations.

Normally,

RF

scanners

are

used

to

record

all

items

at

a

location.