Product

Specifications

are

created

for

each

distinct

product.

Numeric

Tests,

Descriptive

Tests

and

Conditions

make

up

each

Specification.

These

categories

are

further

split

into

Mandatory

and

Optional

requirements.

Numeric

Tests

are

defined

for

each

of

the

measured

parameters

of

the

product.

Information

on

the

target

value,

minimum

&

maximum

operating

limits

and

minimum

&

maximum

hold

limits

are

specified,

along

with

the

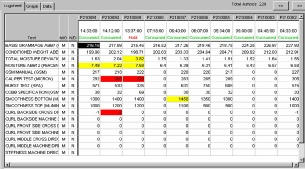

required unit of measure. Tolerances can be either specific values, or percentages of the target.

When

defined

as

Mandatory,

a

result

must

be

entered.

If

Optional,

tests

can

be

entered

on

a

variable

basis

(e.g.

per

Shift,

per

Grade,

etc).

Descriptive

Tests

cover

all

tests

that

cannot

be

measured

numerically,

for

example

appearance. Again, these can be either Mandatory or Optional.

Quality

Recording

is

event

driven

as

items

are

produced.

Where

possible,

Quality

Recording

can

be

interfaced

directly

with

Supervisory

Control

systems

and

intelligent

testing

equipment.

The

system

confirms

the

suitability

of

the

product

as

test

results

are

recorded.

If

all

tests

are

inside

the

operating

tolerances,

the

material

will

be

allowed to progress to the next workcentre or moved into stock.

If

any

test

is

outside

operating

tolerance,

but

inside

the

hold

limits,

the

system

will

alarm

the

operator

If

any

test

is

outside

the

hold

limits

an

alarm

will

be

raised.

Recommendations

are

available

for

re-grading

or

diverting

out

of

specification

products.

Used

in

conjunction

with

Machine

Running

Orders

and

Order

Enquires,

operators

have all of the information to hand to allow quick decisions to be made for sub-standard production.

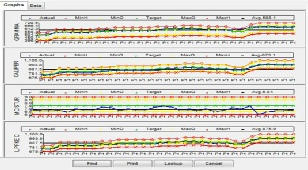

Machine Operating Conditions can also be defined. These cover aspects of Machine set-up, such as flows,

levels, temperatures, etc, as well machinery configuration. Machine Conditions can be recorded either manually,

or through direct interfaces with your instrumentation or DCS. Data can also be recorded through remote hand

held devices, and automatically uploaded. Production operators have access to this information for ‘best run’

set-up.

ascman : quality control

© ascman ltd 2018

“Specialist IT solutions for roll-based, cores and flat sheet industries”

Product Specifications

Mandatory / Optional Tests

Numeric / Descriptive

Inner/Outer Control Limits

Real-time Results Recording

Interface to Testing Equipment

Warnings / Alarms

Non-Conformance Handling

Re-grade, Divert, Re-make

Quality Analysis / Reporting

Machine Operating Conditions

Best Run Information

Product

Specifications

are

created

for

each

distinct

product.

Numeric

Tests,

Descriptive

Tests

and

Conditions

make

up

each

Specification.

These

categories

are

further

split

into

Mandatory

and

Optional

requirements.

Numeric

Tests

are

defined

for

each

of

the

measured

parameters

of

the

product.

Information

on

the

target

value,

minimum

&

maximum

operating

limits

and

minimum

&

maximum

hold

limits

are

specified,

along

with

the

required

unit

of

measure.

Tolerances

can

be

either

specific

values,

or

percentages

of

the

target.

When

defined

as

Mandatory,

a

result

must

be

entered.

If

Optional,

tests

can

be

entered

on

a

variable

basis

(e.g.

per

Shift,

per

Grade,

etc).

Descriptive

Tests

cover

all

tests

that

cannot

be

measured

numerically,

for

example

appearance.

Again,

these

can

be

either

Mandatory or Optional.

Quality

Recording

is

event

driven

as

items

are

produced.

Where

possible,

Quality

Recording

can

be

interfaced

directly

with

Supervisory

Control

systems

and

intelligent

testing

equipment.

The

system

confirms

the

suitability

of

the

product

as

test

results

are

recorded.

If

all

tests

are

inside

the

operating

tolerances,

the

material

will

be

allowed

to

progress

to

the

next

workcentre

or

moved

into

stock.

If

any

test

is

outside

operating

tolerance,

but

inside

the

hold

limits,

the

system

will

alarm

the

operator

If

any

test

is

outside

the

hold

limits

an

alarm

will

be

raised.

Recommendations

are

available

for

re-grading

or

diverting

out

of

specification

products.

Used

in

conjunction

with

Machine

Running

Orders

and

Order

Enquires,

operators

have

all

of

the

information

to

hand

to

allow

quick

decisions

to

be

made

for

sub-

standard production.

Machine Operating Conditions can also be

defined. These cover aspects of Machine set-

up, such as flows, levels, temperatures, etc, as

well machinery configuration. Machine

Conditions can be recorded either manually, or

through direct interfaces with your

instrumentation or DCS. Data can also be

recorded through remote hand held devices,

and automatically uploaded. Production

operators have access to this information for

‘best run’ set-up.

ascman : quality

© ascman ltd 2020

“Specialist IT solutions for roll-based,

cores and flat sheet industries”

Product

Specifications

Mandatory / Optional

Tests

Numeric / Descriptive

Inner/Outer Control

Limits

Real-time Results

Recording

Interface to Testing

Equipment

Warnings / Alarms

Non-Conformance

Handling

Re-grade, Divert, Re-

make

Quality Analysis /

Reporting

Machine Operating

Conditions

Best Run Information